Customer Stories

Delcon - Electronic Relays

Delcon electronic relays are used in industrial automation systems. They are typical electronic products in that they have a circuit board which is enclosed in a plastic box. Delcon is a great example of how an effective use of a powerful ERP system in a small company can keep productivity and profitability high.

Using subassemblies to streamline batch manufacturing

There are about 90 different products, and the sales followed roughly the typical 80/20 rule for sales volume.

So the manufacturing is always in two main parts: the circuit board manufacture and the final assembly and testing. The products are standard design and made to stock with a certain batch size, typically 500, but depending on the exact product.

Before ERP - Inefficient business processes

Before implementing Manu Online ERP, they were often making the wrong items at the wrong time.

Many times products were being delivered late, or at least the customer would have liked to receive them quicker, even if deliveries were being made as promised. A spot check on the shop floor revealed an interesting fact. Someone was assembling product that was not on the backlog report. However, there were different products customers were waiting for that were not in stock or being manufactured. People were simply making the wrong stuff.

The simplified reason for this was that a short time before there had been a quiet period and the production planner had opened a work order for a standard batch of 500 of a common product. This batch was now being taken to completion, which took about five days.

The obvious solution to this would have been to move to “leaner” manufacturing techniques, perhaps reducing batch size. However, we started to consider the concept of making to stock vs. making to order and if there was something we could do to exploit commonality in the product structure to shorten lead times.

Are we making to stock or making to order?

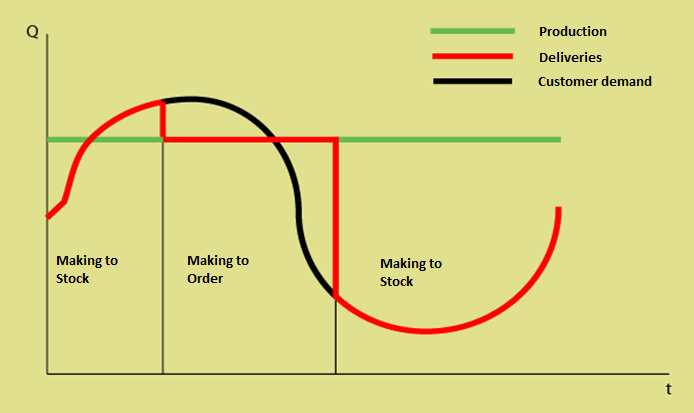

After some reflection on this, we came to the conclusion that the answer is “both”. It depends on the product and the situation with the order book. It changes with time and it cannot be set as a firm manufacturing strategy. In short, when it is busy, we are making to order and when it is quiet we are making to stock.

Make it complicated to make it simple

The solution to the problem was to change the product structure or work order process from a single level product structure/process to a four-level product structure/process. This sounds like we were introducing complexity for the sake of it, but we let the computers handle the complexity. What we were aiming for was to exploit the commonality of the lower parts of the product structure so that when we were making stuff to stock we could leave it later in the production process before we were committed to making a certain final product. So different configuration relays could have the same SMD components, but different manually soldered components. As some relays were sold with branded packaging and labels, this could also be held off to the latest stage.

Old product structure |

New product structure |

| Circuit board | Part board (the reflow solder board) |

| Box and packaging | Finished board (board with hand components soldered) |

| Relay (white label) | |

| Relay (OEM or branded label) |

How the ERP system helped

Manu Online has a real-time scheduler that is also keeping clear record of what materials are allocated to which orders. This is for materials at all stages of the manufacturing supply chain: final goods inventory, work orders (work in progress), subassembly inventory, component inventory, and open purchase orders. In addition, there is an immediate reaction to any changes in requirements, most typically new orders arriving from customers.

Now the make to stock type of work is pushed further down the process chain to circuit board level, where there is a lot of final product commonality. This allows the work order sizes to be larger at that earlier stage, but faster and smaller at the later stage. The overall result is shorter lead times for customer orders, even during busy times. When you walk into production with a copy of the order book now, you see people making stuff that is actually needed.

The end result

Delcon runs a lean organisation so that profitability can be maintained even with a turnover around $1 million. In practice there is no administrative staff as engineers and owner manager can use the tools of Manu Online Enterprise Edition to manage the business processes with little effort. Manu Online plans the work and purchasing based on preset default rules.