Manufacturing

Manufacturing

Introduction to Manufacturing in Manu Online

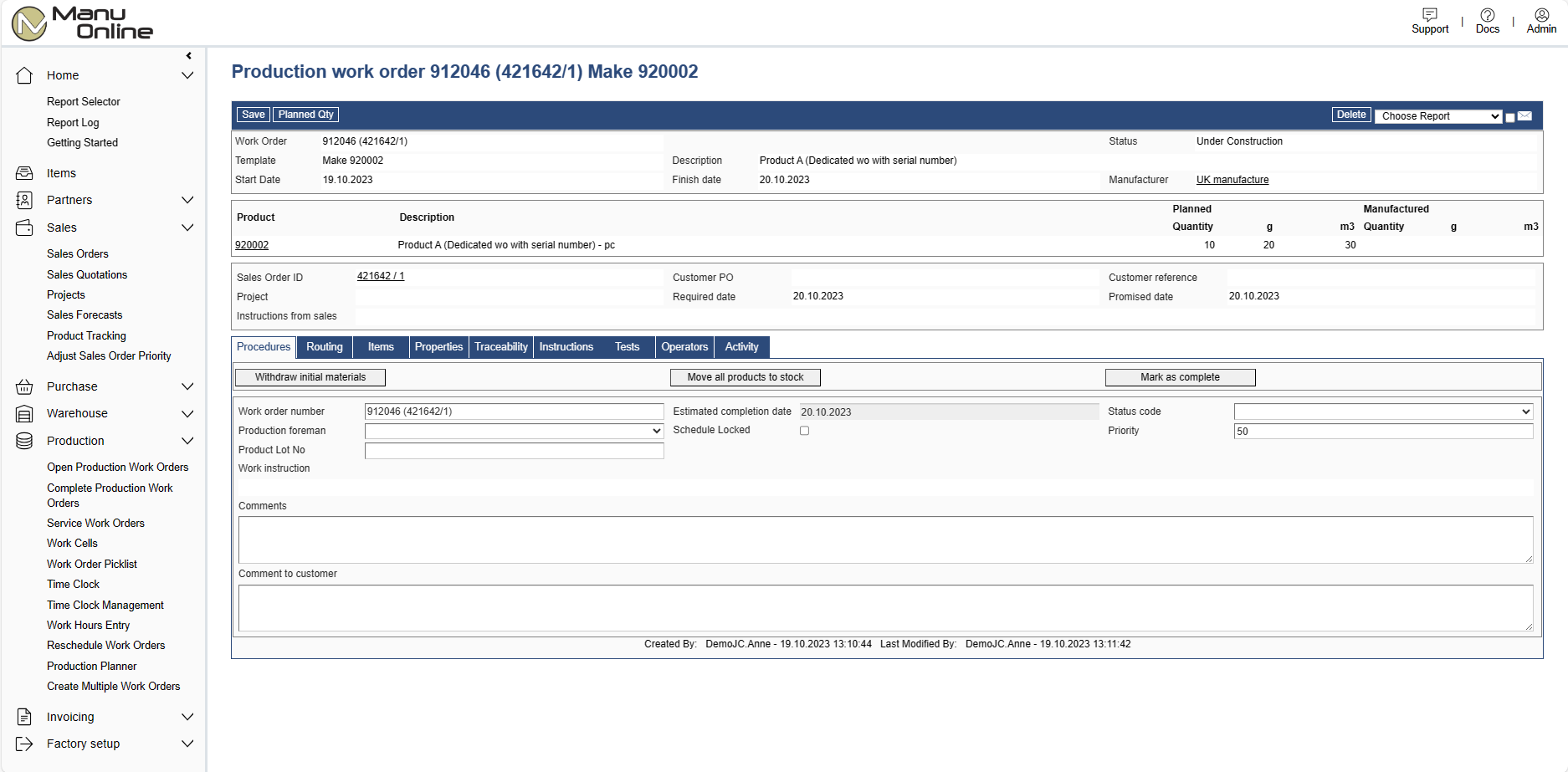

The Production section contains facilities for manufacturing. The central part of the system is the production work order. There is an optional service work order which covers non-product related activities within the system. Production work orders consume items and produce one or more products. Service work orders also consume items but do not produce products but can create invoices (e.g. time and materials jobs).

Production work orders are the key for transforming consumed Items (materials, labour, machine, subcontract or other) into products or semi-finished materials. When a work order is opened for a product, it is based on the manufacturing template defined in the item card’s Manufacturing tab. The template includes the planned item consumption, the route of the work and the properties which define the configuration of the work order process.

Work orders can be opened to fulfil a clear demand for items – a sales order line (or lines) or for subassmeblies, a higher level work order’s requirements. Work orders can also be opened in anticipation of demand (the “make to stock” process). The scheduling system will, automatically and in real time, allocate work order product to demand higher level demand (sales or work order) as this is created in the system. Correspondingly a work order will create demand for consumed items. When using the “dedicated” work order feature then a sales order line will get a work order dedicated to it that by passes any free materials (the “make to order” process).

Work orders can take place in the home factory or can be allocated to a subcontractor. If a subcontractor is used, the subcontractors’ personnel can administer the work order if they have been given a user name for the system – however, this is an optional feature.

Production work orders may have a routing between work cells if this is specified in the template. This is called “Multi step routing”. The route can be adjusted for each individual work order while it is open. If the optional multistep routing is not used, the work order will be opened with a default route of one step in one cell. Cells can have a marked capacity by day.

The work order is the collection point for all costs associated with doing the work. Costs are always obtained by recording the use of Items for a work order either manually or automatically. The inventory value of a product created by a work order is the sum of all Item costs written to the work order, averaged by the number of products created. A work order can produce multiple different products “by-products”.

Manufacturing requirements

A production planner needs to know what orders to open, when to open them and what quantities to open them for. Factors to be taken into consideration of this planning are customer requirements, inventory requirements, sales forecasts, available materials and available capacities. Some of this information is available from the screens. More detailed analysis will require printing out reports.

The system keeps a real time track of item allocation to inventory and to open work orders. This item allocation covers all types of items, so available materials are allocated from inventory, but allocated labour can be seen either in total or by production cell. This allocation system is based on open sales order demand, and demand created for semi-finished products by open work orders of a parent product. Work orders can always be opened for a greater quantity than is shown by requirements. This will create free, available product in inventory which can be allocated in real time as salesmen enter new sales orders. When opening a new work order, the system will display these planned requirements (demand which is not yet in another work order) and by default a new work order will have these demand elements to it in date order. However it is possible to manually select the allocation when the order is opened or then later by rescheduling (see the Scheduling chapter later in this handbook).

If the on-screen information is insufficient, then check reports that provide further details on the manufacturing requirements:

- Manufacturing to start

- Work order material shortage

- Manufacturing needs detail

- Factory loading analysis

- Work cell loading analysis

- Delivery schedule

Using production work orders

The use of production work orders depends on the manufacturing strategy which is either defined for the whole company or alternatively by product line in the company. Rarely is it worthwhile evaluating all the different choices for an individual product.

The following are factors that need to be considered:

Basic issues:

- Make-to-stock, Make-to-order or Engineer-to-Order?

- Predefined product structure or product structure set at sales time?

- When is the work order opened?

- How are consumed items taken from stock in work order?

Advanced issues (require optional features):

- Traceability: serial numbers and/or lot numbering?

- Using multistep routing?

- Manufacturing at a subcontractor?

Make-to-order or Engineer-to-Order?

There is not a black and white line in Manu Online. We understand that sometimes a product is standard and made to stock and sometimes it is customised and a one off is needed. Also in slack times popular products may be made to stock, but in busy times everything may be made only to customer order.

In a pure Make-to-Stock situation, ensure that the full product structure is defined in the item card manufacturing tab. Do not use the Dedicated work order or open work order automatically check boxes. Open the work order from the production menu.

In Make-to-Order, use the dedicated work order check box on the sales order line and also the open work order automatically. When the sales order is activated, the work order will be opened as well.

In Engineer-to-Order, use the dedicate work order check box on the sales order line, but in addition modify the product structure on the sales order line by pressing the Edit structure and properties button. This allows you to manually configure the product, or copy and paste a product structure from an external system, for instance a CAD program. Create one or a number of items which are “template” products. These should reflect the different generic product types. Put into each product the generic product structure. This is the list of parts which are common to all products that will be based on this template product. Quantities can be exact or of no relevance at this time.

When the product is sold, then edit the product structure in the sales order line to add or remove the component parts, or change quantities. Use the dedicated work order check box to fix the link of the resulting work order to the sales order line, and typically use the automatic work order opening check box so that the work order is opened when the sales order is activated.

The work cell screen and backflushing materials on a single step route

Backflushing is a way to save a lot of data entry. Backflushing items causes them to be issued to a work order according to plan either at the beginning or completion of a step.

In many cases of simple manufacturing, a process is started without knowing exactly how many products will be produced. For example in injection moulding a machine may be run until all the raw plastic is used, but it is not considered necessary to measure the exact amount of plastic consumed. In this case backflushing materials on a work order with a single step and closing the work order automatically can be used to make the data entry most simple.

On the work cell screen when the step is closed, the operator will be prompted to enter the amount of product produced and also the amount of scrapped product. The total of these two will be used to count the amount of raw materials used.